Intelligent Tensile Tester distribution|tensile testing system : services The literature lacks tensile force distribution studies for reinforcements along the length of the back-to-back MSE wall. Hence, an attempt was made to validate the study of Yang et al. ().GRS (geosynthetic reinforced soil) walls were utilized to validate a computational model for the tensile force distribution using MIDAS GTS-NX (Midas GTS-NX, 2016) a .

webGet Inspired. Discover. Create. Type your favourite songs and create perfect playlist. Magic!

{plog:ftitle_list}

Resultado da Search: "imperium" HOT NEW. 10145,8K. Novinhas Imperium 🇧🇷 1DMTube. 162,8K. R. Novinhos da Imperium RiverSP85. 171,4K. R. Novinhos da .

XLW Intelligent Tensile Tester can be used to determine physical mechanical properties of plastic films, laminated materials, flexible packaging materials, .A tester integrates seven independent test procedures, including tensile test, peeling test, tearing test and heat sealing test; thus, providing users with a variety of test items. A variety of . Intelligent damage classification for tensile membrane structure based on continuous wavelet transform and improved ResNet50 . richer feature information, and can be used to represent more complex data distributions. Currently, Wigner-Ville distribution, Hilbert . The core area of the planar tensile membrane structure test bench is a . A uniform tensile force was applied perpendicularly at a rate of 3 mm/min using a universal tensile tester to the bonded surface of the specimen. Prior to the tensile test, the coated surfaces were prepared identically to the coating substrate. . Particle size distribution of intelligent TO@CA microcapsules (c). SEM image of MWCNTs (d).

CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging . The literature lacks tensile force distribution studies for reinforcements along the length of the back-to-back MSE wall. Hence, an attempt was made to validate the study of Yang et al. ().GRS (geosynthetic reinforced soil) walls were utilized to validate a computational model for the tensile force distribution using MIDAS GTS-NX (Midas GTS-NX, 2016) a . Critical in composite testing is alignment due to anisotropy, where material properties vary based on force direction.Aligning tests with the fiber orientation is vital for accurate results, especially in the aerospace industry where composites face high-tensile-stress applications. Various gripping mechanisms are available for ambient, sub-ambient, and high . Vibration of tensile cables commonly occurs in the engineering structures such as cable-stayed bridges, which may have negative effect on the driving comfort and safety, and further lead to the fat.

Why perform a tensile testing? Tensile testing plays a crucial role in materials science and engineering for several reasons: Material Characterization: Tensile testing is used to characterize the mechanical properties of a material, including its yield strength, ultimate tensile strength, modulus of elasticity, and ductility.This information is crucial for understanding how a .Read our tensile testing and materials testing guide to find out about tensile strength test, compression testing and the universal testing machine. Enquiries + 4401522 401375 [email protected] Search. Client Area. Request a quote. Basket. Menu. Close. Calibration & Repair. Calibration & Repair.

tensile testing system

From easy-to-use, hand-held force and torque gauges to software-controlled tensile testers and torque systems, we have the solution for your tension, compression and torque testing requirements. . Global distribution. UK Head office. 6 International offices. 52 Distributors worldwide. Contact us +44 (0)1403 799979 [email protected]. PPT Group .Testing Principle The specimen is clamped between two heads of the fixture, and the two heads make relative movement. Through the force sensor on the moving chuck and the displacement sensor built in the tester, the force and displacement Labthink Instruments Co., Ltd. 144 Wuyingshan Road, Jinan, P.R.China (250031) Phone: +86-531-85068566 FAX: +86-531 .at room temperature tensile test method to determine the sample size. We used the electronic universal testing machine DNS-300 for tensile tests. Figure 4 shows the macro fracture morphology of the joint. We use the temperature field distribution detection system of FSW based on a multichannel K-type thermocoupleSimplify the replacement of test jigs. The multi joint feature on the AGX-V2 series connects the jigs to load cells. It enables all jigs – including tensile, compression, and bending jigs – to be quickly and easily connected. Now, it is no longer necessary to replace heavy joints, which simplifies the replacement of test jigs.

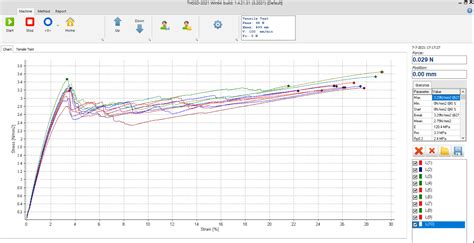

Abstract In this study, we investigated the improvement in carbon fiber (CF) bundle tensile tests. To effectively evaluate the mechanical properties of CF using the fiber bundle tensile test, measurement of system elongation correction considering nonlinear behavior and Weibull analysis using fitting of stress–strain curves was conducted. Shear-lag theory analysis .ITT – INTELLIGENT TENSILE TEST. An advanced feature for measuring specimens with an outside layer creating fragments that eventually fall off. A typical application is the tensile testing of reinforcing steel bars with a layer of oxide or rust. ITT FUNCTIONALITY DEMONSTRATION BM – BRIDGE MEASUREMENT. RES – RESEARCH & DEVELOPMENT FEATURES

Intelligent Electronic Tensile Testing Machine We have manufactured hot sale XLW PC Tensile Testing Machine, which is used to determine physical mechanical properties of plastic films, laminated materials, flexible packaging .Tensile tests are performed on “printed” metal specimens. . Reliable Products Thanks to Intelligent Testing Technology. 3D printers are also on the rise in the metals industry. . The company focuses on the development, assembly and .Tensile testing can also be used to verify that materials adhere to minimum strength and elongation requirements. From suspension bridge cables to safety harnesses, lives may depend on the quality of your materials and products so .

This study investigates the correlation between various micromagnetic signature patterns and the yield and tensile strengths of carbon steel (Cr12MoV steel as per Chinese standards). For this purpose, back-propagation neural network (BP-NN) models are established to quantitatively predict the yield and tensile strengths of carbon steels. The accuracy of .CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups Quasi-static tests (0.001 s(-1)) were performed using an electromechanical universal testing machine, whereas a split Hopkinson tensile bar apparatus was used for testing at high strain rates .

Tensile and shear fractures are significant mechanisms for rock failure. Understanding the fractures that occur in rock can reveal rock failure mechanisms. Scanning electron microscopy (SEM) has been widely used to analyze tensile and shear fractures of rock on a mesoscopic scale. To quantify tensile and shear fractures, this study proposed an . Tensile strength is an important control parameter for the design and stability analysis in rock engineering. In order to reveal the influence of elastic modulus on tensile strength test results, Brazilian splitting tests were carried out on specimens with different strengths, such as mudstone, white sandstone, green sandstone, red sandstone, and marble.

tensile testing software

Considering bamboo as a 2-phase natural composite made up of vascular bundles (reinforcement or fiber) and matrixes (ground tissues) on the scale of micromechanics. By test of bamboo specimens and analysis of microscopic images of their cross sections, the distribution of vascular bundles along the axial and radial of bamboo culm were investigated. The relations .

From the experimental test results, the tensile behavior of UHPFRC could change from strain hardening behavior to softening behavior as the specimen size increased, whereas the increase of fiber size did not alter the strain hardening behavior of UHPFRC. The tensile performance of UHPFRC was highly dependent on the fiber size and specimen size.

CB609 AXIAL TENSILE TESTER available at BoeingDistribution.com. Click here to Buy Now! . Please contact your Boeing Distribution Sales Representative for further assistance. Sales department +1.305.925.2600. [email protected]. Login Assistance close. Tensile testing may be performed at a very basic level by simply using a handheld force gage where the gage measures the pull force applied on a sample, product or component in order to determine the maximum force. At the other end of the instrumentation spectrum are extremely sophisticated tensile testing systems equipped with advanced .2.1 Dynamic flexural tensile strength test The dynamic flexural strength numerical test is conducted by the coupled SHPB system [75], as shown in Figure 1(a). The coupled SHPB system Figure 1 Description of the dynamic flexural tensile simulation: (a) Modeling of the numerical three-dimensional SHPB

tensile testing equipment

tensile tester safety

20 de ago. de 2023 · Siga o PORTAL DO ZACARIAS no Facebook, Twitter e no Instagram. Entre no nosso Grupo de WhatApp e Telegram. Já a mulher alega que, neste momento, .

Intelligent Tensile Tester distribution|tensile testing system